Sandwich panel - a plate for creating walls and ceilings, which consists of upper and lower covering sheets and a filler between them. As a filler sandwich panels for prefabricated buildings, various materials are used:

-

Basalt wool;

-

Expanded polystyrene;

-

Polyurethane foam;

-

Fiberglass threads;

The cover sheet is made of steel with a thickness of 0.5 mm. Galvanization or polymer coating reliably protects the steel surface from corrosion and mechanical damage. Industrial sandwich panels with profiled sheets are characterized by additional strength, can be connected in a "castle" type, when the protrusions of the profile of one panel are included in the recesses of the adjacent one.

ADVANTAGE OF PANELS IN INDUSTRIAL CONSTRUCTION

-

Resistance to precipitation and temperature changes (the range of use of panels is from -60 to +55 ° C);

-

Environmental cleanliness, sanitary and fire safety;

-

High-quality sound and heat insulation, which leads to lower heating costs;

-

Service life about 50 years;

-

Universality: it is possible to erect industrial buildings and constructions of other purposes (temporary houses, residential cottages, shopping centers, warehouses, garages, sports complexes, etc.)

WHY SANDWICH PANELS ARE OPTIMAL FOR CONSTRUCTION OF STEEL BUILDINGS

-

A small mass of panels provides several benefits at once: (You do not need a powerful foundation; You will save on transportation; You will not need to attract heavy equipment.)

-

The panels are convenient to mount.

-

Thanks to the modular design, damaged sheets can be easily replaced and, if necessary, even completely disassemble the building and assemble it in a new place.

-

The construction of industrial buildings from sandwich panels does not require additional costs for exterior decoration. Thanks to the wide color gamut, you can choose the sheets of the desired shade.

Basic warranty

Choosing reliablecladding systems in the form of sandwich panels from PK VESTA, you get high quality guarantees and the most comfortable conditions from the brand during the lifetime operation of the building. For new sandwich panels purchased in the Russian Federation, a 1 year warranty is provided by default.

Extended Warranty

It is also possible to get a 5 year warranty on non-combustible sandwich panels with individual consideration of the operation of objects in different regions of Russia and on international markets (the presence of the ocean or water resources, high levels of humidity indoors, the purpose of the building, a certain technology, etc.)

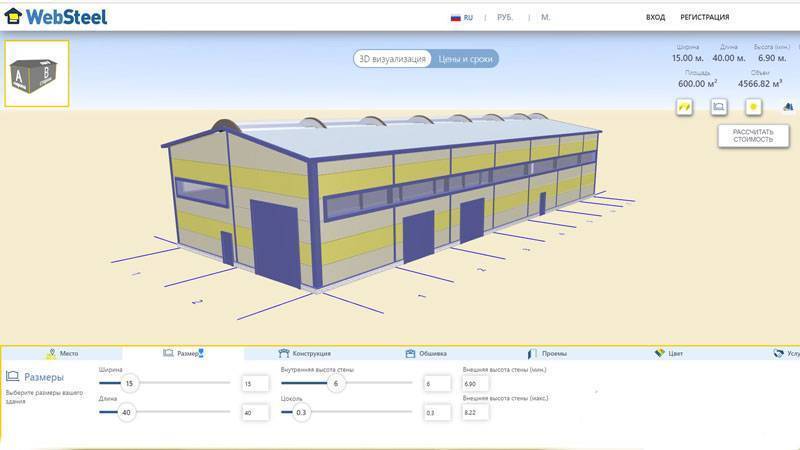

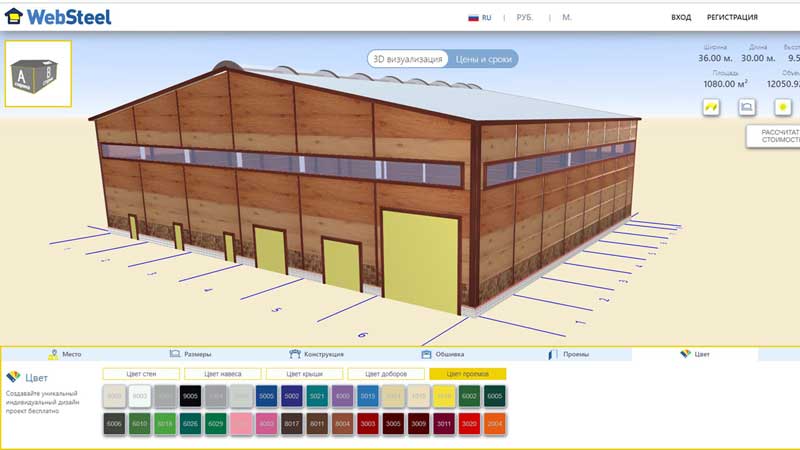

Following a new concept, PK VESTA has created opportunities for international customers to design individual buildings themselves in the new WebSteel online service via the Internet withing the wide range of technological capabilities of the plant, followed by ordering a building kit anywhere in the world.

Depending on the design decisions, it is possible to create any type of steel structure for free: gable, lean-to, adjacent to the old building, flat roof, buildings with elevations, etc.

The client can choose hundreds of options for individual color combinations based on the RAL catalog or textures for wood, stone or brick for walls and roofs (panel, horizontal strip, checkerboard pattern, alternating colors in several rows, etc.)

WebSteel - innovative i-cloud 24/7 service, which was created in 2011. in the Russian city of Tula on the basis of a new philosophy of serving customers online in construction idustry - "Smart Techo Design"

We have implemented an innovative browser-based 3D engine for instant visualization of individual buildings in real time, completely leaving the old resource-intensive Flesh developments.

The steel used in our lightweight metal structures has the highest strength-to-weight and tensile strength ratios among other traditional building materials in the world. Plus, steel is the leading frame material for buildings and infrastructure, with a market share in many developed countries of more than 50% in the non-residential and multi-story residential industry (Steel Recycle Institute)

The engineering group of the PK VESTA plant necessarily takes into account the basic loads at the construction site (snow, wind and seismic) in the design scheme of the building, which can reach the maximum design values (snow load - up to 600 kg / sq., Wind load - up to 100 kg / sq. m. and seismic load - up to 10 points on the Richter Scale)